There are many reasons why, over the last 60 years, plastic

has increasingly replaced other materials such as glass and metal. Plastics are

cheap and easily processed, allowing large amounts of design freedom including

shape and colour. They are low in weight, but high in strength, making lifting

and transporting easy while providing a hygienic and safe method of packaging.

However, despite the many positive attributes of plastic, it

does have negatives. Two important issues are the greenhouse gas emissions

resulting from its production and incineration after use, together with the

degradation of the natural environment due to plastic pollution.

How to address these challenges is an area of intense debate,

which, despite the stakeholder consensus on the need for action, results in

conflicting opinions on the best solutions. At the epicentre of the plastic

debate are the so-called single-use plastics and the use of plastics as a

packaging material.

So, what are the options for packaging? Revert to older

materials such as glass or metal? Consider new materials produced from

renewable plant-derived raw materials? Adopt compostable materials? Increase recycled

content? The options are manifold, and each one provides different benefits

while introducing new challenges.

At NNFCC, we have worked with many companies, including

packaging manufacturers and brand owners, to define and assess these options and

produce rational fact-based conclusions.

In a recent project, NNFCC worked with UK based clear

packaging producer Stäger to assess a range of material options available as sustainable

replacements to their current material of choice: PET plastic.

Stäger’s packaging can be seen on retail shelves showcasing food,

confectionery, cosmetics, and toiletries. With quality products requiring

quality packaging, the technical performance of the material is paramount. In Stäger’s

case, this means a transparent material capable of being folded with a high-quality

finish.

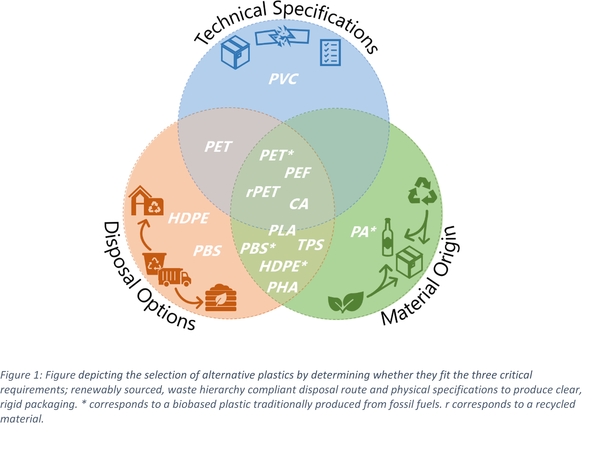

An initial screening exercise identified several candidates

worthy of further investigation, which included polylactic acid, cellulose

acetate, ‘biobased PET’ and the new PET alternative: PEF.

Each material option was considered in relation to its

performance characteristics, availability, cost, environmental impacts and fit

with near-term waste infrastructure and legislation.

For many consumers the link between plastic, crude oil, and

the climate creates a strongly negative perception about plastic products. The

shift to renewable plant-derived raw materials can break this perception link

and lead to real sustainability benefits. Each of the identified materials are

fully or partially produced from renewable raw materials and therefore fulfil

the desire to move away from crude oil.

It would however be incorrect to link the use of renewable

raw materials during the production of a product to any of its end-of-life or

waste disposal opportunities. In this respect, a plastic product produced from

renewable raw materials, correctly called a biobased product, could be as

durable as any petroleum plastic or as biodegradable as paper.

It is important that packaging materials are designed with

consideration for their eventual disposal. From an environmental perspective, the effective

recycling of a plastic product generally represents the preferred disposal

route. However, despite the fact that nearly all types of plastics can be

recycled, the majority are not. This is due to the complexity of waste

collection, the sorting of mixed plastics, issues with contamination preventing

recycling, and the resulting (often unfavourable) economics of recycled plastic

versus virgin plastic production.

Within some stakeholder groups there is a belief that

recycling issues point to the need to move towards biodegradable materials.

Although superficially attractive, biodegradable materials still require

defined disposal routes, since being biodegradable cannot be seen as a license

to allow waste products into the environment. It is also not a panacea for the

problem of plastic marine litter.

In respect to biodegradable packaging, this means that

packaging must be designed for, and capable of entering, food or garden waste

collections destined for composting facilities. The use of the compostable

packaging standard, EN13432, ensures the suitability of packaging for

composting although a range of other factors including facility acceptance also

influence the effectiveness of this route.

Stäger currently produces packaging incorporating 60%

recycled and 40% virgin-grade PET. Recycled PET has a considerably lower

environmental impact relative to virgin-fossil PET. The environmental benefits

of using recycled PET coupled with the high recycling rates for PET underpin

Stäger’s current sustainability strategy.

A shift from virgin fossil to virgin biobased PET would

enhance Stäger’s sustainability credentials. Considering a range of

environmental impacts, the move to biobased PET (with commercially available 30%

renewable content) would reduce the environmental impacts by over 10%. Furthermore,

the commercial development of PET with 100% biobased content is being actively

pursued by several leading brands including Coca Cola and PepsiCo, offering the

potential for greater environmental gains.

As a responsible packaging producer already producing

products with high recycled content, Stäger were keen to understand the options

to introduce compostable materials into their product offering. Although a

switch to cellulose acetate in Stäger’s applications does present some

technical challenges, it also presents the opportunity to switch to a

compostable product. Cellulose acetate is certified for both home composting (when

<0.106mm in thickness) and industrial composting.

Compostable products provide an alternative waste disposal

option ideal for products which are hard to recycle, such as mixed or food

contaminated products. If, however, recycling is considered feasible and

realistic, then the advantages of composting should be carefully weighed against

the benefits of recycling. Other important considerations include whether the

use of compostable packaging enables the effective management of other waste

i.e. diverting food waste from incineration or landfill; or what the likelihood

is of consumers placing the material in the correct disposal system.

Overall any material choice will come with positives and

negatives which need to be carefully balanced.

The environmental impacts of plastics can be reduced in both

production and disposal. During production, the use of recycled and/or

renewable raw materials should be assessed, and the product’s end-of-life

should be considered, ensuring that the product is easily recyclable or

compostable. Adopting a life cycle thinking approach to material choice and product

design ensures that sustainability is considered from the outset.

Ultimately the best way to reduced plastic pollution is to stop

polluting with plastic. Consumers, producers and governments should all take

responsibility and ensure that all plastic waste not only makes its way into

the appropriate waste facilities but also that the appropriate waste facilities

are in place.